If you are in the business of selling meat, you understand the importance of keeping your product fresh and at the appropriate temperature. As you know, meat and meat products are easily microbial breeding and go bad. It must be preserved at a suitable temperature to keeps well and avoid harmful microbial breeding.

And in the meat and meat products manufacture industry, safety and hygiene levels are imperative. Also, it needs to keep their quality and flavor when you want to increase of shelf life.

One of our clients, a meat business owner in Thailand, was facing several challenges with their existing storage facility. He wants to custom a freezing cold room for they meat products to storage.

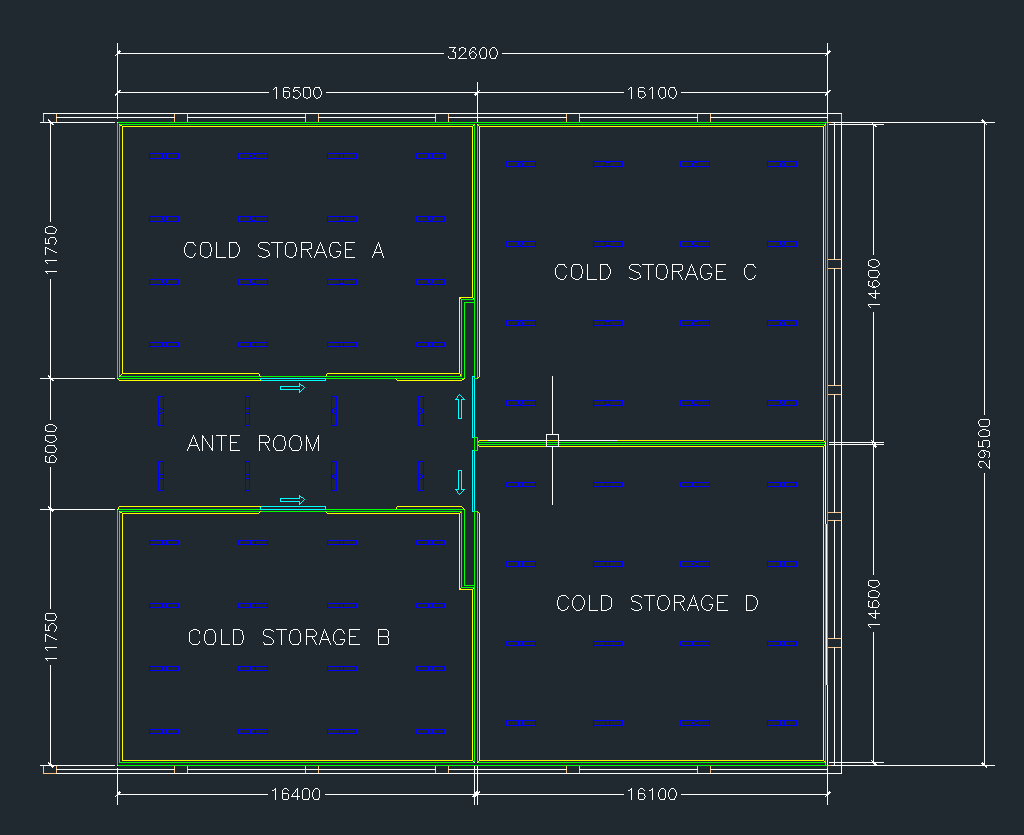

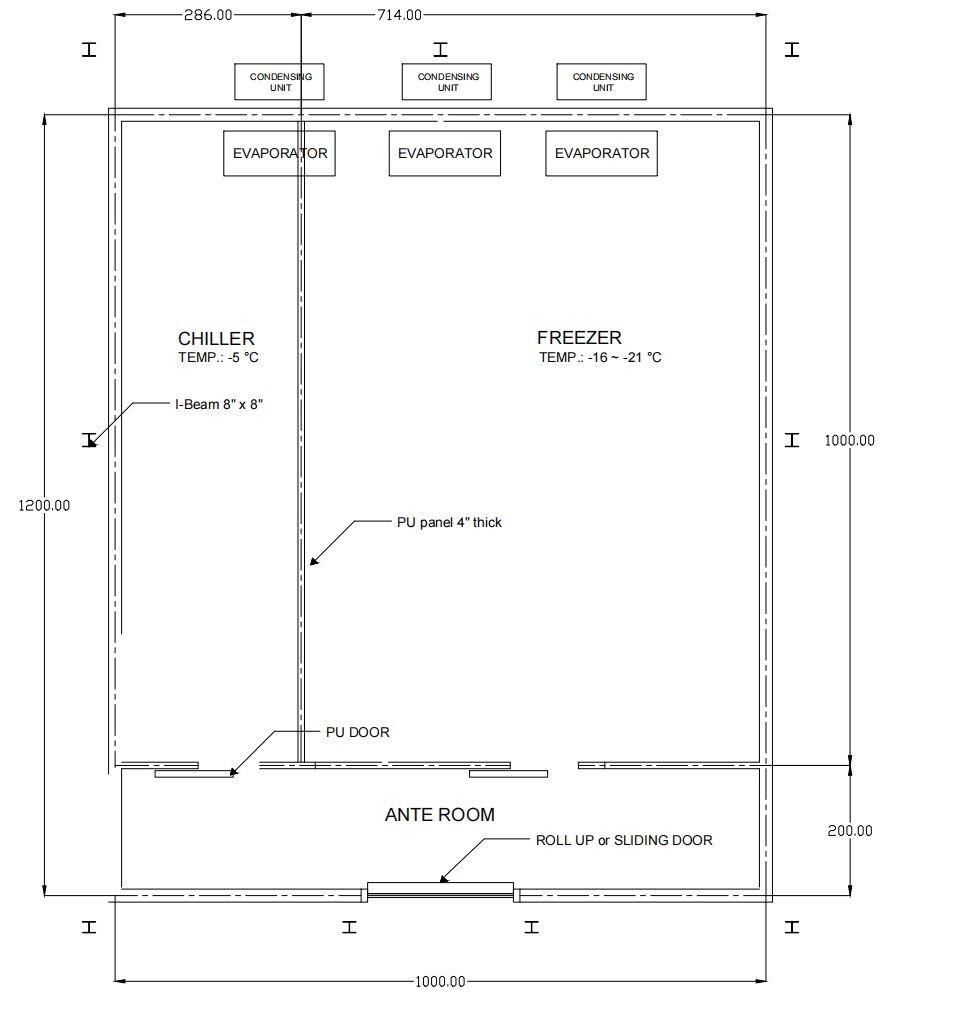

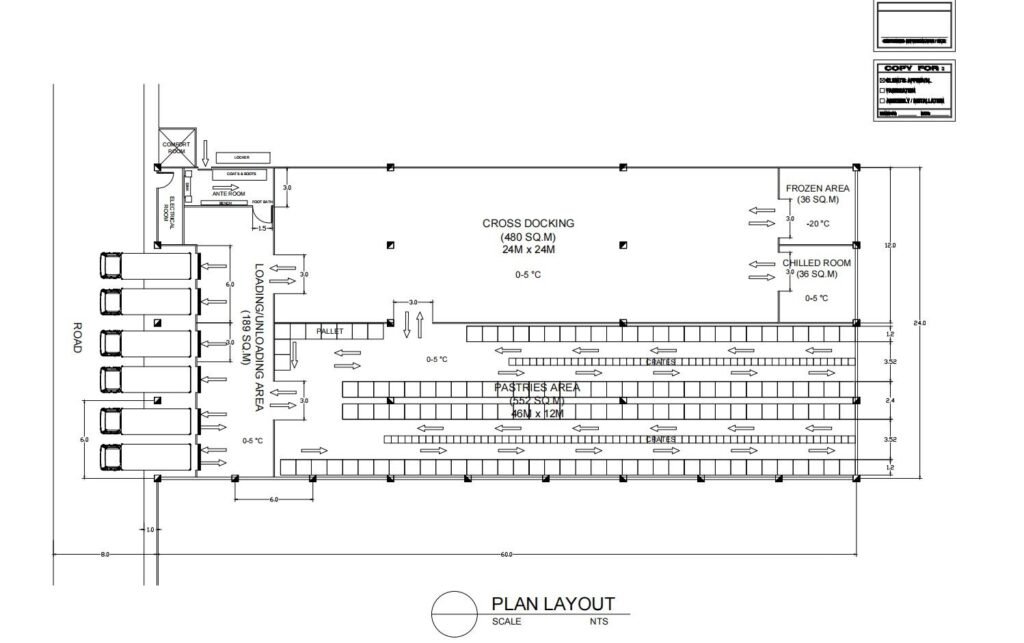

Our team of experts visited the client's factory and in-depth understanding of the meat industry with customer and listen to their cooling project needs. After that, our engineer designed freezing room suitable for their application.

Our technician team consider all elements of your industry and working processes when creating a cold room for your business. Contact Our Team if you are interested in building a new cold room for your products.

Project Specifications

The turn-key cold room design by customer's basic requirements, we have configured a 30HP Bitzer Semi-Hermetic compressor and customized a cooling fan with heavy cooling capacity. All the cold room panel from 150mm insulated PU panel with PPGI sheet.

Convenient for customers to easily operate the equipment. The refrigeration unit has been pre welded with copper pipes and connected to the pipeline of the air cooler before shipment. After receiving the goods, they only need to install the cold storage panel according to the drawings.

We have made holes in advance according to the pipeline to reserve the installation position for the side plate of the fan installation.

Cold storage panel must be at least 150mm thickness PU panels with fire flame retardant, and sealant should be applied before installing the panel to prevent cold leakage. Many people like to apply sealant as a door sealant after installing the cold storage. The gap generated in this way is not conducive to insulation and thus generates water mist.

The customized cold room exceeded our client's expectations. They now have a state-of-the-art facility that keeps their meat fresh and at the appropriate temperature. The room has also helped them reduce their energy bills, and they have seen a significant improvement in their profit margins.

A cold room is an essential component of any meat business that wants to succeed. By investing in a customized cold room, our client in Thailand now has a competitive edge in the market. If you are in the meat business and are facing similar challenges, consider investing in a customized cold room.

Feedback from our customer

"I recently purchased a freezing room from this company, and I couldn't be happier with my purchase. The room allowed me to store large quantities of meat without having to worry about spoilage. The installation process was seamless, and the team was professional and knowledgeable. They were able to answer all of my questions and provide me with valuable advice on how to maintain the room to ensure optimal performance."

If you’d like to find out more about how to design a cold room for your products, welcome to Contact Our Team. We would be happy to help and advising.

GET IN TOUCH